Bag Splitting

Main function of the Bag Splitting Machine is to take out the material inside paper or plastic bags without mixing with bag pieces and to separate bag scraps for recovery. This Machine is extensively used in different industries like cement and gypsum for recovery of the material from faulty bags or quick discharging the material for using in the next process.

WORKING PRINCIPLE OF SC BAG SPLITTING MACHINE

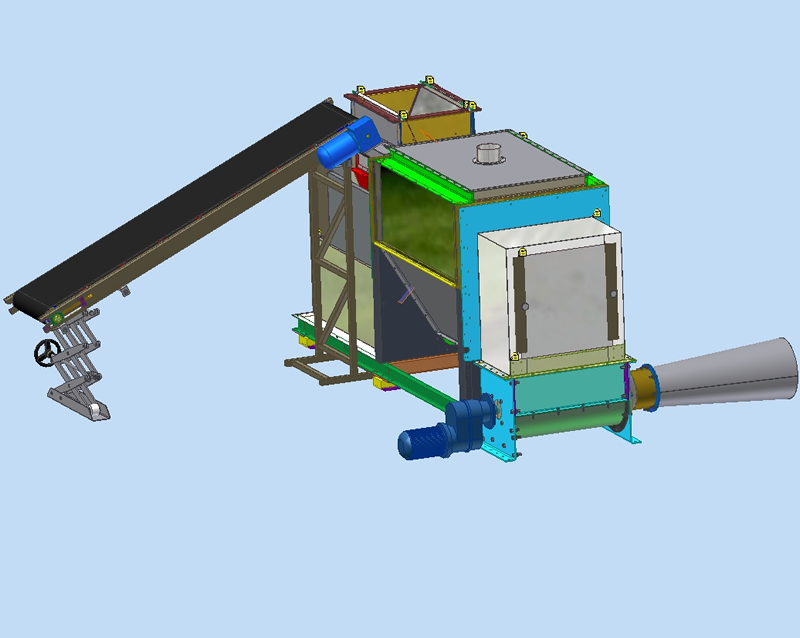

Bag Splitting Machine basically consists of main chassis, splitting, sieving and bag scrap discharge units. A height adjustable feeding conveyor unit can be included in the system depending on the application conditions and client requirements. Bags are torn by disc knives which are adjustable according to bag characteristics in the splitting unit and transported to the sieving unit by screw conveyor. Specially designed sieving unit separates material and bag scraps completely from each other. Clean material collected in the lower chamber is transferred by a suitable system which is designed according to application conditions, while cleaned paper bag scraps are compressed and collected in a bag placed inside the paper exit cone.

WHY TO USE SC SPLITTING MACHINE?

- 100% domestic product

- 7/24 call center support for all over Turkey

- On-site technical support for all over the world

- Simple construction

- Easy transfer to the location of need.

- Use of low pressurized air

- Standardized product quality