Precise Check and Reject System

Packing check scale

Packing check scales are used for checking the weights of packing during the packaging operation, where using paper or plastic bags in standard weights, e.g. 25, 50 kg are used. Through this system, packing correctly filled up within tolerance is separated from the ones incorrectly filled up out of tolerance. It has been widely used in all industrial areas, including cement and construction chemicals, where serial packing operations are performed. As weight tolerances tighten, their use becomes compulsory.

WORKING PRINCIPLE OF SC PACKING CHECK SCALE

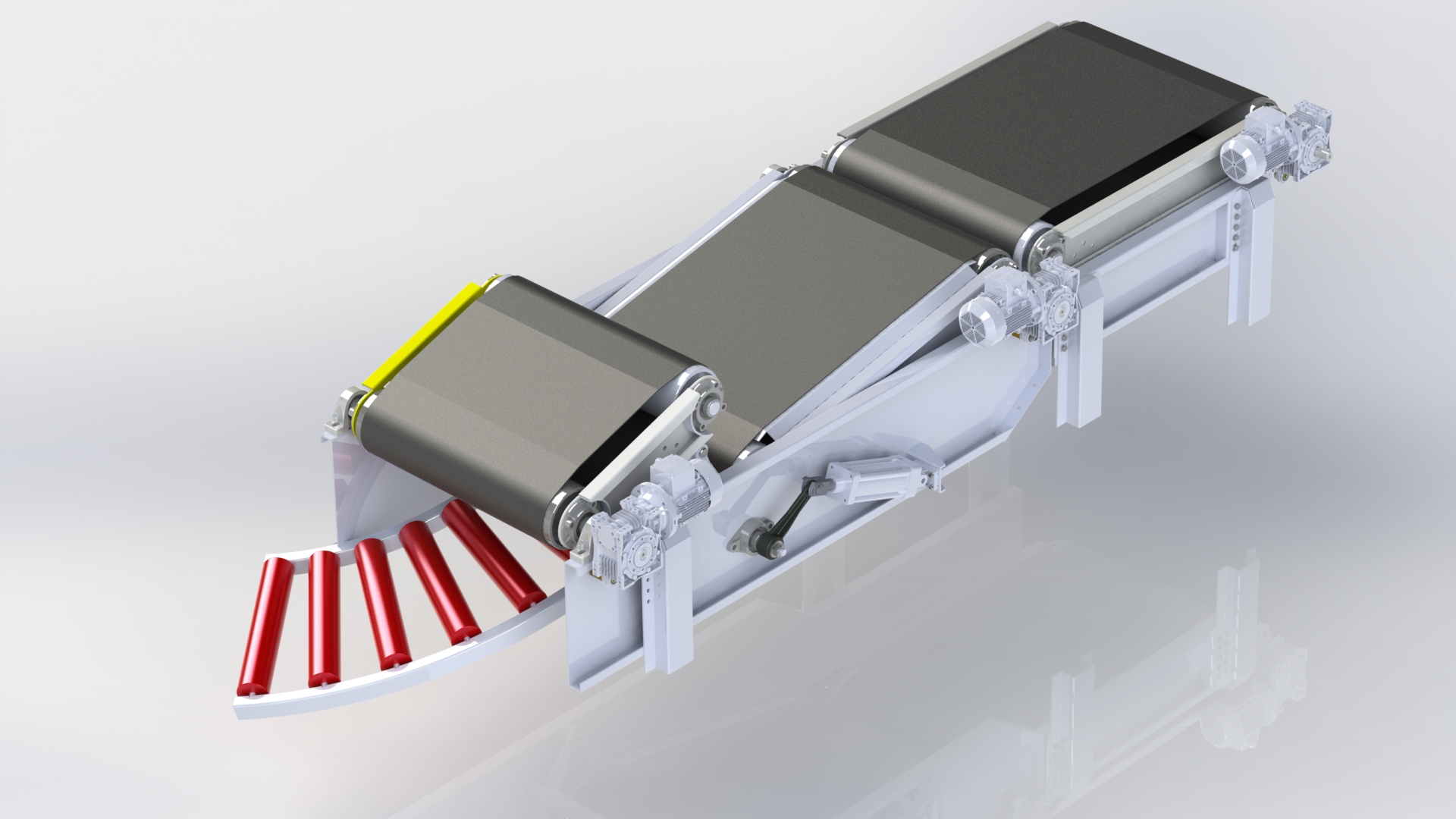

Depending on the request and application conditions, packing check systems with various constructions can be designed and manufactured. However the packing check scale, the main component of the system basically consist of three parts namely; pack inlet roll station, weighing unit and pack outlet roll station with guidance system. The first part, pack inlet roll station regulates the feeding of packs into weighing unit. In weighing unit, the packs are weighed and checked whether filled correctly or not, based on the given tolerances. In the pack outlet roll station, which is third part, packs are routed into two different directions by means guiding means of according to the information obtained from weighing unit.

PRODUCT CAPACITY

Systems in various capacity and precision levels can be designed and manufactured in accordance with the customer requirements and application conditions.

WHY TO USE SC PACKING CHECK SCALE?

- 100% domestic manufacturing

- 7/24 call center support for all over Turkey

- Technical support for all over the world.

- Simple construction

- Easy installation

- Standardized product quality