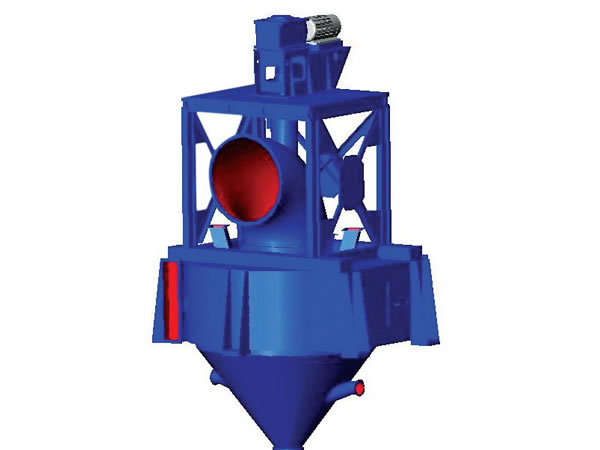

O-Sepa Separator

These high efficiency cyclone separators are released into the market to improve the low efficiency of mechanical separators by recovering the particles. Material, which is fed on to the rotary distribution plate, is directed into the classificatory air flow extracted from tangential inlet duct through fixed safety valves. Separator feed is approx. 2.5 kg feed / m3 air flow. Due to the gravitational force of the particles and inward air flow, a classificatory horizontal vortex develops. While fine fragments raise upwards along with the gases for the next collecting, coarse fragments fall down and discharged from the bottom part of the container. The fineness is only regulated over the rotor speed. As the speed increases, so does the fineness. Air flow is independently controlled by separator ID fan. Material distribution is effectively provided by distribution plate and buffer plates along the inner wall. The design of the air inlet duct and safety valves allow the uniform distribution of the incoming air. The ratio of rotor height / plate diameter decides the process time in the separation area. Further improvements in the O-Sepa separators has reduced the air flow speed by nearly 30% without comprimising the efficiency.