|

SHEET METAL PARTS

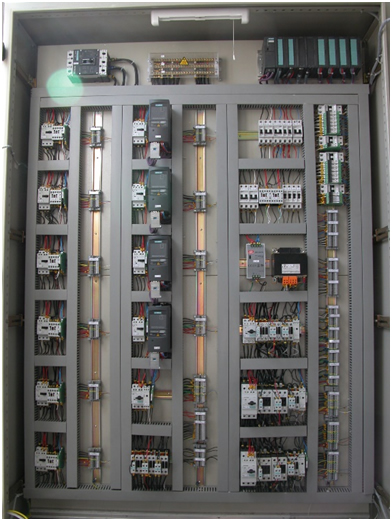

Panel Frame

It is made of electrostatic powder coated, oven dried, perforated and pressed, 2mm DKP sheet metal and erected by means of special galvanized parts in the corners and galvanized bolts.

The panel has 4 lifting eyes for transportation purposes.

Front, rear, side and top covers are made of one-piece, pressed sheet metal and coated with electrostatic painting. It is painted with RAL 7032 and oven dried at 220 °C after surface cleaning and granodising.

Front covers, sealed and with latching type locks, are attached with stable hinges in minimum three points. Side covers are removable and convenient for extensions.

Covers, including cable entries, are protected against water and particularly dust with IP54 protection class. A cooling fan exists in the middle of lower part of the first compartment door and there are also heaters with appropriately distributed power ratings to avoid condensing. Fans and heaters are controlled by thermostats.

All panel parts are earthed with stranded copper conductor with a consistent cross-section.

Mounting plates supporting all devices and device groups are made of perforated galvanized or electrostatic powder coated sheet metal profiles.

Dimensions:

Height h: 2000 mm+100 mm

Base width w: 700 mm

Depth d: 500 mm

Lighting system is available in panels and also there is a 2A grounded plug outlet for control purposes. Tray layouts and single line diagrams are placed on the panel doors and in project boxes.

|

INTERNAL ELECTRICAL PARTS

Siemens, Telemecanique or Möller branded circuit breakers are used. Their breaking capacity is 50 kA and they have auxiliary contacts enough in number which is specified in the wiring diagram. Main cable connections are protected against direct hand contact. In open position, padlocks can be attached.

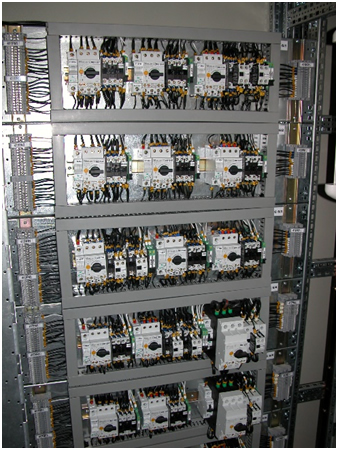

Motor Protection Circuit Breakers

Siemens, Telemecanique or Möller branded products, thermal-magnetic characteristics, 1NO+1NC auxiliary contact and 1 NO error signal contact in minimum. Compact circuit breakers and contactors are available for motor outputs higher than 90 kW. Furthermore selected circuit breakers are equipped with accessories which are able to carry out all functions in the sample projects. In 0 (open) position, padlock mechanisms for safety reason and label holder are provided. |

|

|

|

|

|

|

Contactors

Siemens, Telemecanique or Möller branded power contactors are used. Coil and control circuit is AC, coil voltage is 220 VAC. Coil voltages of auxiliary contactors are specified in the wiring diagram. These coils are protected against hand contact. Contactors are selected according to duty class AC3.

Fuses

No fuses are needed as thermal-magnetic circuit breakers are used in the power circuits. In control circuits, Siemens, Telemecanique or Möller circuit breakers with matching current values are used. All switching materials are labeled in accordance with the project references. |

|

|

|

|

Busbars

They are manufactured from electrolytic copper. Phases are painted in accordance with TSE norms. No holes are drilled for cable outgoings. They are connected to the branching bar coming from each compartment via terminals. Cable shoes are used for cross-sections over 50 mm2. Larger cable outgoings are connected via busbars. Contact surfaces in the connections are cleaned by using fine grained sandpaper (zero). Busbar are isolated by heat shrinkable sleeves. All busbars (including circuit breaker outlets) are covered with Plexiglas protections against direct contact. Busbar cross-sections are selected according to the short circuit calculation.

Cables

Cables are selected in accordance with the TSE standards and short circuit calculations.

Colors

Power circuits (380 V): black (consistent cross-section)

Control circuits:

:22 V common terminal, green 1,5 mm2

:220 V active terminal, grey 1,5mm2

:24 VAC active terminal, yellow 1,5mm2

:24 VAC active terminal, pink 1,5mm2

:special measurement circuits, purple 1,5mm2

:24 VDC + red 1,5mm2

:24 VDC - blue 1,5mm2

All cable terminals are core-ended and reference numbers specified in the project can be seen on the cables.

Cord ends and cable shoes are crimped with special crimping tools. Cables inside the panel are entirely flexible. Cable channels are supplied by Legrand, Phoenix or Wiedmüller.

Control and Signal Voltages

The voltages are supplied by isolation transformers with consistent power ratings. In panels, isolation transformers are provided for contactors. The outlet of the isolation transformer is protected by magnetic switch.

Connection Terminals

They are supplied by Phoenix or Weidmüller and have labels for each group or single connection. Covers are provided in the group ends and stoppers at the starting and finishing elements. The cross-sections for power circuits are consistently selected, while 11,5 mm2 in control circuits.

Current Transformers

The current transformers, class 1 and Alce, EMGE or Bortrans branded, are selected according to the short circuit current ratings.

COMMON FEATURES of MCC PANELS

TIP: SC.MCC.800.2100.500.

SC-MCC-AS panels with dimensions (800.2100.500. mm) are used. In MCC panel, PLC outputs are isolated by relay. Power analyzer is provided in the power inlet of MCC panel. Lighting system is available in MCC panels. There are ventilation fans in the MCC panels. |

|

|

|

|